mini excavator bucket teeth types Find the right teeth for your excavator bucket size and application. Compare H&L, Hensley and . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

0 · tiger teeth for excavator bucket

1 · takeuchi mini excavator buckets

2 · replacement teeth for bobcat bucket

3 · mini excavator bucket teeth replacement

4 · excavator with tiger teeth

5 · excavator bucket teeth replacement

6 · bobcat mini excavator bucket teeth

7 · bobcat bucket teeth chart

The Cat® 301.8 Mini Excavator delivers power and performance in a compact size to help you work in a wide range of applications. ALL DAY COMFORT. Choose either a canopy or a sealed and pressurized cab equipped with air conditioning, adjustable wrist rests, and a suspension seat option to help keep you working comfortably all day long.

Learn about the different types of excavator bucket teeth and how they are used for various projects and materials. Find out the advantages and disadvantages of each type and see examples of their applications in mining, demolition, landscaping, and more.

Let’s dig into the most common excavator bucket teeth types: Chisel Teeth: .Find the right teeth for your excavator bucket size and application. Compare H&L, Hensley and . The right teeth for your application can significantly boost efficiency, minimise . This article will cover all you need to know about mini excavator bucket teeth, .

In this blog, we’ll explore the types of materials used in excavator bucket teeth and the factors . Learn the types, material, compatibility, and benefits of different excavator .

tiger teeth for excavator bucket

Learn how to select the right bucket teeth for your skid steer loader, compact . Matching the bucket teeth on your excavator, loader or backhoe to the job cuts . Learn how to identify and choose the best excavator bucket teeth for different .

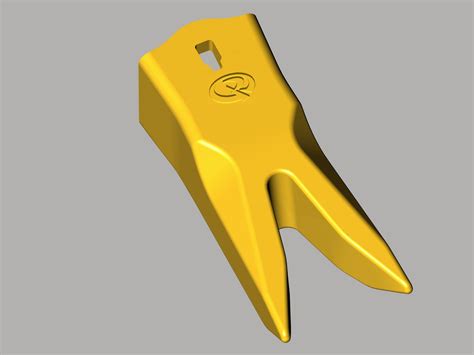

Learn about the different types of excavator bucket teeth and how they are used for various projects and materials. Find out the advantages and disadvantages of each type and see examples of their applications in mining, demolition, landscaping, and more. Let’s dig into the most common excavator bucket teeth types: Chisel Teeth: Versatile, great for general digging and trenching in loose soil. Rock Chisel Teeth: Heavy-duty, designed to handle hard, rocky terrain. Single Tiger Teeth: Sharp, excellent for penetrating compact soil and rock.Find the right teeth for your excavator bucket size and application. Compare H&L, Hensley and ESCO styles of bucket teeth with CNH branded teeth. The right teeth for your application can significantly boost efficiency, minimise downtime, and extend the lifespan of your machine. This guide explores the top 4 factors to consider when selecting the perfect excavator teeth for your project needs.

This article will cover all you need to know about mini excavator bucket teeth, including how to determine the ones best suited for your applications. This holds true for compact machines like our 1-ton mini excavator with a 13.5 HP engine , .

In this blog, we’ll explore the types of materials used in excavator bucket teeth and the factors that contribute to their durability. Understanding these aspects can help you choose the right bucket teeth for your specific needs, saving you time and money in the long run. Learn the types, material, compatibility, and benefits of different excavator bucket teeth for various digging conditions. Find tips and maintenance advice to optimize your excavator's performance and longevity. Learn how to select the right bucket teeth for your skid steer loader, compact track loader or mini excavator based on application, compatibility and wear resistance. Find out the benefits of high-quality bucket teeth and the best practices for maintaining them. Matching the bucket teeth on your excavator, loader or backhoe to the job cuts wear and tear on the teeth and the bucket. And it lets your equipment work to its highest potential. Many times, a new bucket will include teeth that are ill-suited for your particular job.

Learn how to identify and choose the best excavator bucket teeth for different materials and jobs. Tiger teeth offer the most penetration in fine sand and clay, while chisel and rock teeth are suitable for soil and gravel. Learn about the different types of excavator bucket teeth and how they are used for various projects and materials. Find out the advantages and disadvantages of each type and see examples of their applications in mining, demolition, landscaping, and more.

Let’s dig into the most common excavator bucket teeth types: Chisel Teeth: Versatile, great for general digging and trenching in loose soil. Rock Chisel Teeth: Heavy-duty, designed to handle hard, rocky terrain. Single Tiger Teeth: Sharp, excellent for penetrating compact soil and rock.Find the right teeth for your excavator bucket size and application. Compare H&L, Hensley and ESCO styles of bucket teeth with CNH branded teeth. The right teeth for your application can significantly boost efficiency, minimise downtime, and extend the lifespan of your machine. This guide explores the top 4 factors to consider when selecting the perfect excavator teeth for your project needs. This article will cover all you need to know about mini excavator bucket teeth, including how to determine the ones best suited for your applications. This holds true for compact machines like our 1-ton mini excavator with a 13.5 HP engine , .

In this blog, we’ll explore the types of materials used in excavator bucket teeth and the factors that contribute to their durability. Understanding these aspects can help you choose the right bucket teeth for your specific needs, saving you time and money in the long run.

Learn the types, material, compatibility, and benefits of different excavator bucket teeth for various digging conditions. Find tips and maintenance advice to optimize your excavator's performance and longevity. Learn how to select the right bucket teeth for your skid steer loader, compact track loader or mini excavator based on application, compatibility and wear resistance. Find out the benefits of high-quality bucket teeth and the best practices for maintaining them.

Matching the bucket teeth on your excavator, loader or backhoe to the job cuts wear and tear on the teeth and the bucket. And it lets your equipment work to its highest potential. Many times, a new bucket will include teeth that are ill-suited for your particular job.

takeuchi mini excavator buckets

$10K+

mini excavator bucket teeth types|takeuchi mini excavator buckets